About Us

Pentarugs : Art & Tradition

Pentaugs are made with the finest craftsmanship, using the finest raw materials. We pride ourselves on the rigorous detail and quality of every rug we make. The design, materials and craftsmanship of our rugs are all held to the highest standard.

Sheep Shearing

At Pentarugs, we carefully source the world’s finest wool from the lush green hills of New Zealand and the vast open landscapes of Australia. New Zealand wool is prized for its natural softness and warmth, while Australian wool is known for its fine, strong fibers that create a beautifully smooth, resilient texture. Together, they form the foundation of rugs that are as durable as they are luxurious.

Every stage—from shearing and spinning to dyeing and weaving—is guided by our commitment to craftsmanship and quality. The result is a rug that doesn’t just cover your floor—it elevates your space.

Carding & Spinning

At Pentarugs, every strand of wool begins its transformation through two essential processes: carding and spinning.

Carding is the first step, where raw wool fibers are gently separated, aligned, and cleaned using carding brushes or rollers. This combing action removes impurities and prepares the fibers for smooth, even processing.

Next comes spinning, where the carded wool is drawn out and twisted into yarn using traditional spinning wheels or modern machines. This step gives the yarn its strength, consistency, and texture—laying the foundation for the rich, resilient weaves in every Pentarugs rug.

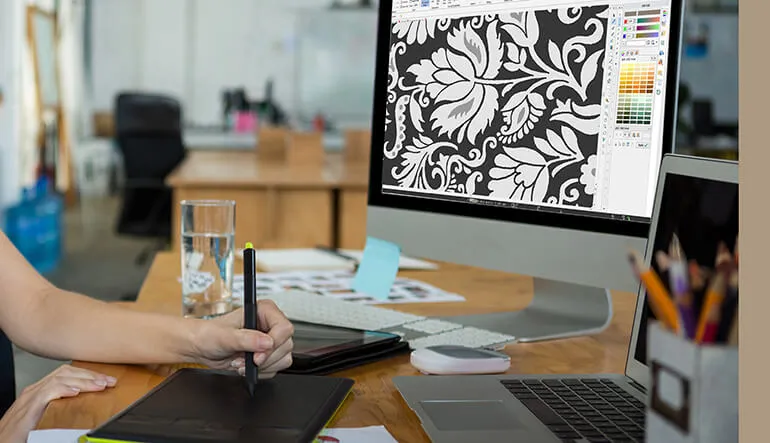

Design Process

At Pentarugs, we blend timeless artistry with innovative design to create rugs that are not only beautiful but deeply meaningful. Each piece is a reflection of tradition, skill, and creative vision—carefully crafted to enhance both spaces and stories.

The style, size, color palette, and pattern of every rug go beyond aesthetic appeal. They reveal the origin, cultural heritage, and craftsmanship behind the design. From bold geometric layouts to intricate floral motifs, each pattern carries a unique identity that sets it apart. It’s this thoughtful attention to design that transforms every Pentarugs rug into a lasting work of art.

Dyeing

At Pentarugs, we use traditional hand-pulled wooden frames to prepare our yarns for dyeing. Each strand is carefully held in place and dipped into rich dye pots, absorbing vibrant hues through time-honored techniques. Once dyed, the yarns are hung outdoors to dry naturally under the sun—a slow and deliberate process that can take several hours to ensure lasting color and depth.

Our commitment to craftsmanship and color precision is reflected in our extensive library of over 800 unique dye patterns, each contributing to the richness and individuality of every Pentarugs creation.

Yarn Drying Process

At Pentarugs Global Rugs, our yarns are dyed in an extraordinary palette of over 3,000 distinct colors, offering unmatched depth and variety in every design. To preserve the richness and vibrancy of these hues, the dyed yarn is dried the traditional way—under the natural warmth of the sun. This slow, time-honored process helps lock in the color and ensures that each thread retains its beauty and brilliance for years to come.

Weaving

At Pentarugs, our rugs are brought to life by skilled artisans who use time-honored techniques and simple, traditional tools—a hooked knife, scissors, and a comb. These tools are essential for tying precise knots, trimming the yarn, and beating the weft tightly into place, creating the dense, durable texture that defines our rugs.

Each weaver follows a rug map—a life-sized graph of the design—that guides every knot and color placement with incredible accuracy. Along with the map, all necessary raw materials and design layouts are sent to various weaving centers, where artistry and precision come together on the loom.

Washing

The final washing is a crucial step in the rug-making process at Pentarugs. It not only enhances the natural sheen of the wool but also brings out the depth and clarity of the underlying knots, adding strength and durability to the finished piece.

Using clean, fresh water, the carpets are thoroughly rinsed to remove any remaining dust or impurities. A traditional wooden plank with flat edges is then used to firmly press and scrub the surface, ensuring every fiber is clean and vibrant.

Gultarash

At Pentarugs, our signature high-low carving process adds depth and dimension to every rug. By carefully sculpting the surface, we create intricate, multi-layered edges that enhance the design and give each piece its distinctive character.

Once carved, the rug undergoes hand shearing—a meticulous step where skilled artisans trim away uneven fibers. This process not only refines the texture but also ensures the rug is perfectly shaped and smooth to the touch.

Now, the finished rugs are inspected for quality and then packed and ready to be delivered to your space